ISO 9001 : 2015 ISO 14001 : 2015 ISO 22000: 2018 CERTIFIED COMPANY

FIBC BAGS

FIBC Bags (Jumbo Bags/Bulk Bags), are one of the most effective option of packaging for Storage & Transportation of a various range of solid materials such as Chemicals, Dye-Intermediates, Pharmaceuticals, Minerals, Rubber, and Sugar etc. These bags are manufactured from Tubular/Flat fabric and widely appreciated due to attractive specifications. These bags are custom designed as per client’s requirement, thus we offering bags for both single-trip (5:1) and multi-trip (6:1 or 8:1) purposes. The FIBC bag’s SWL range start from 250 Kg up to 2000 Kg. All our bags are manufactured in accordance with ISO 21898. Concerning the aspects of the avoidance of electrostatic-ignition hazards, up to now four types of FIBCs (A, B, C and D) are in use according to their ability of charge dissipation and/or limiting the energy of possible discharges.4-PANEL BULK BAGS

4-panel bags are constructed with four individual pieces sewn together to form a square structure. When filled, a 4-panel bag will hold its square shape similar to other construction types. Typically, 4-panel bags will hold their shape better than the U-panel bags, and a U-panel bags will hold their shape better than a circular bag.

This bags is very suitable for transporting and storing various types of light and finer raw materials and building materials such as ornamental gravel, split, and garden waste, fire wood and wood pallets.

Advantage of 4- panel FIBC bags:

- Best for storage and transportation since they stack more easily.

- More bags can be stored there while using less storage space.

- The best option for sectors that primarily need to pack, store, and transport solid and uniformly shaped products.

- Due to the bag’s square design and use of tougher materials, finer types of substances can also be transported with ease.

Common Uses & Applications:

4-panel bulk bags can be used to chemicals, Minerals, Foodstuffs, Sugar, Seed, Salt, Rice, Detergents, Grain, Clay, Flour, Plastics, Beans, Fertilizers, Resins, Pharmaceuticals, Cement, Dyes, Nuts, Refractory Products, Beans etc.

Design Options:

The biggest drawback to 4-panel bags is the large amount of stitching required to keep the bag together. This can allow for more areas of the bag prone to failure. However, 4-panel bags are ideal for storage due to the way they hold their shape when filled.

- Safety ratio – 5:1 and 6:1

- SWL – 500kg to 2000kg

BAFFLE / Q -BAGS /FORM-STABLE BAGS

A Baffle / Q bags are extra fabric panels or pieces of string sewn into each of the bag’s four corners. Thus, when the bag is filled, the baffles prevent the sides from bulging out or falling over when being stored or transported, giving the bags a square shape.

Advantage of Baffle / Q-bags:

- Maximum Shipping/Container Optimization

- Exceptional Stacking Capabilities

- Optimizes the product of product stored

- Ideal for Low density Products

- Holds 20-30% more product than Standard FIBC Design

Common Uses & Applications:

Baffled Jumbo Bags can be used to hold any dry flowable product such as grains, seeds, basic and specialty chemicals, minerals, Carbon Blacks, and various foods stuffs. They can be designed to fit any size pallet and are inter model compatible.

Design Options:

Baffle Bags can be produced in a circular, U-panel, or 4-Panel format. This package works well with cone tops and Bottoms. Cross Corner lift loops or standard corner loops can be applied to any bag.

Baffle FIBC bags are different from other FIBC bags in the following ways:

- Standard bags tend to bulge if full, whereas baffle bags can be stacked more neatly.

- Contrary to other FIBC bags, baffle bags maintain their shape even after being fully filled because they include baffles on the corners.

- When a typical FIBC bag is fully loaded with items, it might sag significantly. As a result, they are effective for moving some materials like gravel and sand, but they are ineffective for moving finer, powder-like materials like cement, fertilizers, etc. These more upscale goods are best stored and transported in baffle FIBC bags.

- Baffle bags are more space-efficient than their competitors since they may be piled on top of one another and maintain their shape even when completely loaded.

- Safety ratio – 5:1 and 6:1

- SWL – 500kg to 2000kg

U-PANEL/U+2 BAGS:

U panel Bags are an industry standard and the most popular type of construction offering a high Safe Working Loads (SWLs), affordability and Solid Durability.

U panel bulk bags (FIBC) have one (1) continuous piece of fabric for a side, bottom and opposite side panel creating a “U” shape. The remaining sides and top panel are then sewn in to construct the bags.

Advantage of U panel FIBC bags:

- Super Bearing Capacity

- Less Stress at the bottom of the bag

- Square appearance due to vertical side seems

- Best for Fine Products that Sifts

Common Uses & Applications:

U panel bulk bags can be used to hold dry flowable chemicals, minerals, dyes, resins, detergents, food, Sugar, salt, nuts, plastics, grain, clay, Cement, Fertilizers, Seed, Sand, flour, rice, ground rubber, beans, Pharmaceuticals, and refractory products. They can be designed to fit any size pallet and are inter-modal compatible.

Design Options:

U panel bags can be sewn with hemmed panels allowing for extra length and rigidness on vertical walls creating a squarer appearance. The hemmed Panel feature also increases the support of your product. Lift Loops are sewn in with main bag seams optimizing their strength.

- Safety ratio – 5:1 and 6:1

- SWL – 500kg to 2000kg

CIRCULAR/TUBULAR BAGS:

Circular bulk bags have a Circular/Tubular body that is a seamless. With only a top and Bottom Panel sewn into the bag, circular style bags are ideal for fine and hygroscopic materials.

These bulk bags/ FIBC bags are made from single Piece of fabric, turning it into a tube like, cylindrical shape, while it’s sewn at the top and bottom with flat panels and this gives the bag a cylindrical structure.

Eight reinforcing sections are woven into the fabric on the loom so that it may be sewn onto a square foundation with four corners.

Assembled with cross-corner handles.

Seamless tubular design increases their load capability, and at the same time, allows you to stack them on top of the other, saving valuable storage space.

Advantage of Circular FIBC bags:

- Less Stress areas with reduced amount of seams

- Attractive appearance & better strength due to no side seams

- Good for fine particles that sift

- Improved moisture resistance

Common uses and applications:

Circular Jumbo Bags can be used to hold any dry flowable product such as grains, seeds, basic and Specialty chemicals, minerals, Carbon Blacks and various food stuffs, and excel at hygroscopic and finer particle products. They can be designed to fit any size of Pallet and are inter-modal compatible.

Design Options:

Circular bags only have sewing seams at the top of opening area and bottom discharge area of a bag. Circular bags also work well with a cone bottom or full open discharge.

- Safety ratio – 5:1 and 6:1

- SWL – 500kg to 2000kg

UN FIBC BAGS

UN-Certified Bulk Bags are designed to store and ship highly hazardous materials and substances. Designed to handle products that the United Nations considers hazardous material. These are made from highly durable material which is proven to prevent leakage or contamination of the hazardous material by internal or outdoors contamination.

Advantages of UN Bags/ what makes UN bulk bags different from other bags?

- UN-rated bulk bags are manufactured with a higher level of durability than regular bulk bags.

- Standard FIBC bags must follow the industry-required safety ratio of 5:1. On the other hand, UN-approved bags have a remarkable 6:1 safety ratio.

- Hazardous materials need to be transported and stored in some situations. UN-rated bulk bags are specially made to carry and store hazardous items when a regular FIBC bulk bag won’t meet the safety regulations.

- These UN-certified bags provide a lot of benefits, but they also go through a lot of tests to prove their quality, including righting, drop, tear, top lift, toppling, and stacking tests.

- Bags that have received UN approval must adhere to the norms and testing requirements outlined by the organization. Manufacturers of bulk bags with UN certification make sure that dangerous and potentially destructive goods are delivered securely.

Common uses and applications:

Each UN Bag should carry the UN-Symbol mentioned in below table which shall imply the hazard level of the product.

Bags used for packing hazardous goods can only be made after obtaining a UN certificate issued by an authorized and notified laboratory.

UN Bags are also classified according to the Hazard level of the goods they carry.

Four different FIBCs for risky items are woven from polypropylene:-

13 H 1: Woven plastics without a liner or a coating.

13 H 2: Woven plastics with the coating but no inner.

13 H 3: Uncoated with liner, woven plastics.

13 H 4: Woven plastics with liner and coated.

| Degree of Danger | Packing Group | UN-Symbol | max. Volume |

|---|---|---|---|

| High | I | X | 1,5 m3 |

| Medium | II | Y | 3,0 m3 |

| Low | III | Z | 3,0 m3 |

The UN Regulations require 6 tests:

| 1. Top lift test | 2. Drop test | 3. Topple test | 4. Righting test | 5. Stacking test | 6. Tear test |

SINGLE/TWO LOOP BAGS

FIBC Bags can be manufactured with a number of variations in their designs to cater to different requirements for storage and transportation. 1 & 2 Loop FIBC Bulk Bags are constructed using tubular body fabric which directly get extended to create 1 or 2 lifting loops as required. This gives the bags additional strength and makes it economical as there no further requirement of adding additional loops to the bag. The loops are wrapped with coloured sleeves. Usually these One & Two Loop Bags are made with an inner liner to protect the contents from external environment & moisture. These bags find their usage primarily in the agricultural sector but are also used for storing and transporting goods like powders and minerals. These bags can be made from coated or uncoated fabrics as per customer’s requirement and are available with printing upto 4 colours.

Advantages of 1 & 2 Loop FIBC Bags

- Loading efficiency

- Cost-savings

- Customized features for various practical purposes

Common Uses & its Applications

1 & 2 Loop FIBC Bags are used as the preferred packaging solution in industries like agriculture, fertilizer, construction, mining etc. One Two Loop FIBC Bags are perfect for storing and transporting seeds, fertilizers, minerals & powdered raw materials such as cement & sand.

- Safety ratio – 5:1 and 6:1

- SWL – 500kg to 1500kg

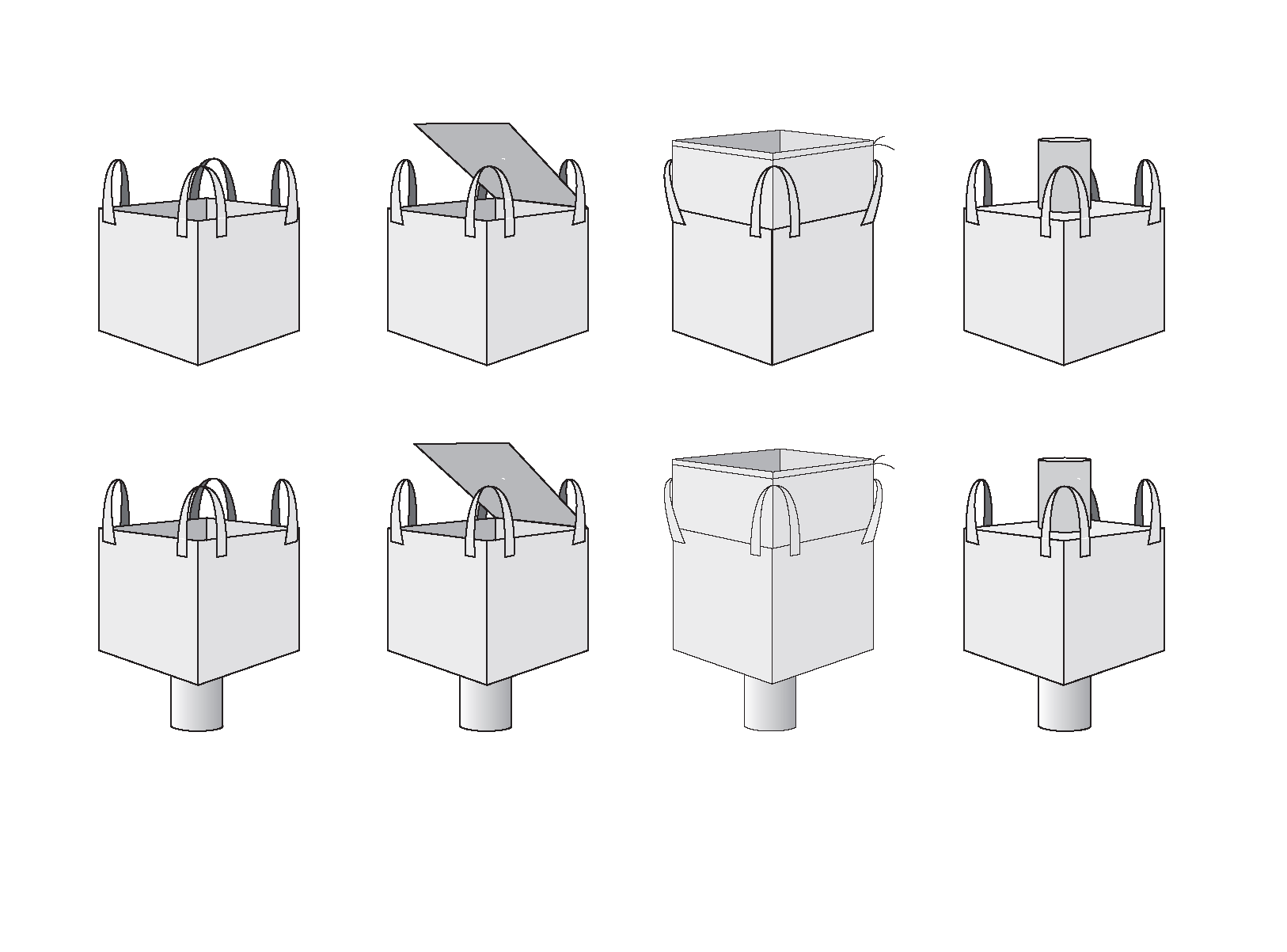

INLET/OUTLET CLOSURES & SEWING PATTERNS

Top Filling Options:-

- Open Top with Hem

- Filling spout

- Filling Spout with Iris/pajama closure

- Skirt/Duffle

- Flaps with Ties

Discharge Options:-

- Full bottom discharge with flaps

- Discharge spout

- Discharge spout with Iris/Bonnet/Pajama or Star/Petal closure

- Discharge spout with Flaps

- Conical Bottom

- Spout with Remote release

Also can do B-Lock with Rope, Velcro closing

Loops Options:-

- 4 corner loops

- 4 cross corner loops

- Loops sewn Inside

- Stevedore loops parallel to each other

- Stevedore loops running through 4loops

- Tunnel Loops

- Single/two loop

- D-Loops

Sewing Patterns:-

- Standard Hirakles stitch

- Hirakles stitch with safety Stitch

- Double Chain stitch

- Single Dustproofing/Siftproofing

- Double Dustproofing/Siftproofing

- Triple Dustproofing/Siftproofing {Double Filler cord + Felt}